Aqua Synergy Solutions

Specializing in Water Management, Waste Water Treatment, and cutting-edge Process Technologies, we bring expertise to redefine industry standards.

About Us

At Aqua Synergy Solutions our commitment is unwavering — we pledge to provide profound knowledge that not only enhances your understanding but significantly contributes to savings and bottom-line growth in your business. Our mission is to empower you with insights that drive efficiency, sustainability, and success.

What Sets Us Apart

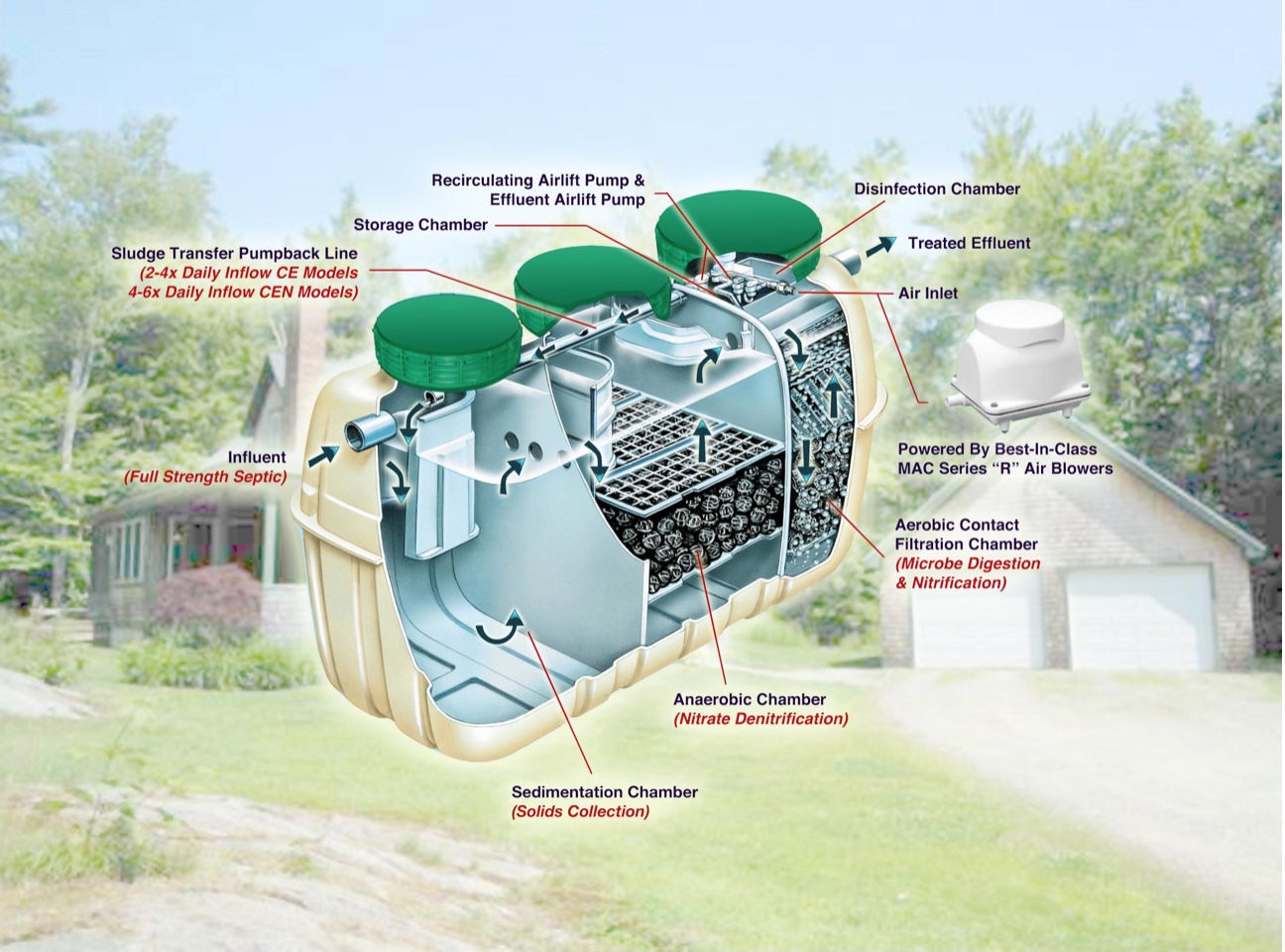

Discover the unparalleled capabilities of Fusion, your definitive solution in water management and waste treatment.

Exceeding Standards

Fusion consistently produces effluent that not only meets but surpasses DWS General limits.

Tailored Solutions

Achieving special limits is a breeze with Fusion, thanks to its adaptability through oversizing or extending the retention time, offering tailored solutions for diverse needs.

Adaptable to Any Job Site

Fusion is highly adjustable to site conditions, ensuring optimal performance in various environments.

Effortless Installation

With only four pipe connections required, Fusion boasts easy and hassle-free installation.

Energy-Efficient Operation

Operating with a power consumption range from 60w (1,700 lpd) to 336w (15,000 lpd), Fusion combines efficiency with environmental consciousness.

Minimal Maintenance

A mere six-monthly service requiring just one hour ensures continuous functionality, with no check-ups needed between service intervals.

Fusion’s Impact Across Africa

- Schools

- Farms

- Single households

- Lodges and guest houses

- Industrial effluent

- Petrol stations

- Shopping centres

- Commercial buildings

- Villages

What to do with fusion

- Renew the UV lamp on an annual basis.

- Replace the blower diaphragm and air filter every four years.

- Utilize detergents and chemicals that are compatible with septic tanks.

What not to do with fusion

- Avoid using detrimental substances such as bleaches, chlorines, antibacterial sanitizers, detergents, and soap, as they can harm the bacteria essential for the proper functioning of any biological plant.

- Do not dispose of inorganic matter down the drain.

- Refain from flushing paper hand towels or newspaper down the drain, as these types of paper degrade slowly and may lead to blockages in the sewer system.

- Do not introduce petrol, oil, grease, or engine cleaner into the system. Additionally, avoid flushing paint or thinners down the sewer line.

Gallery

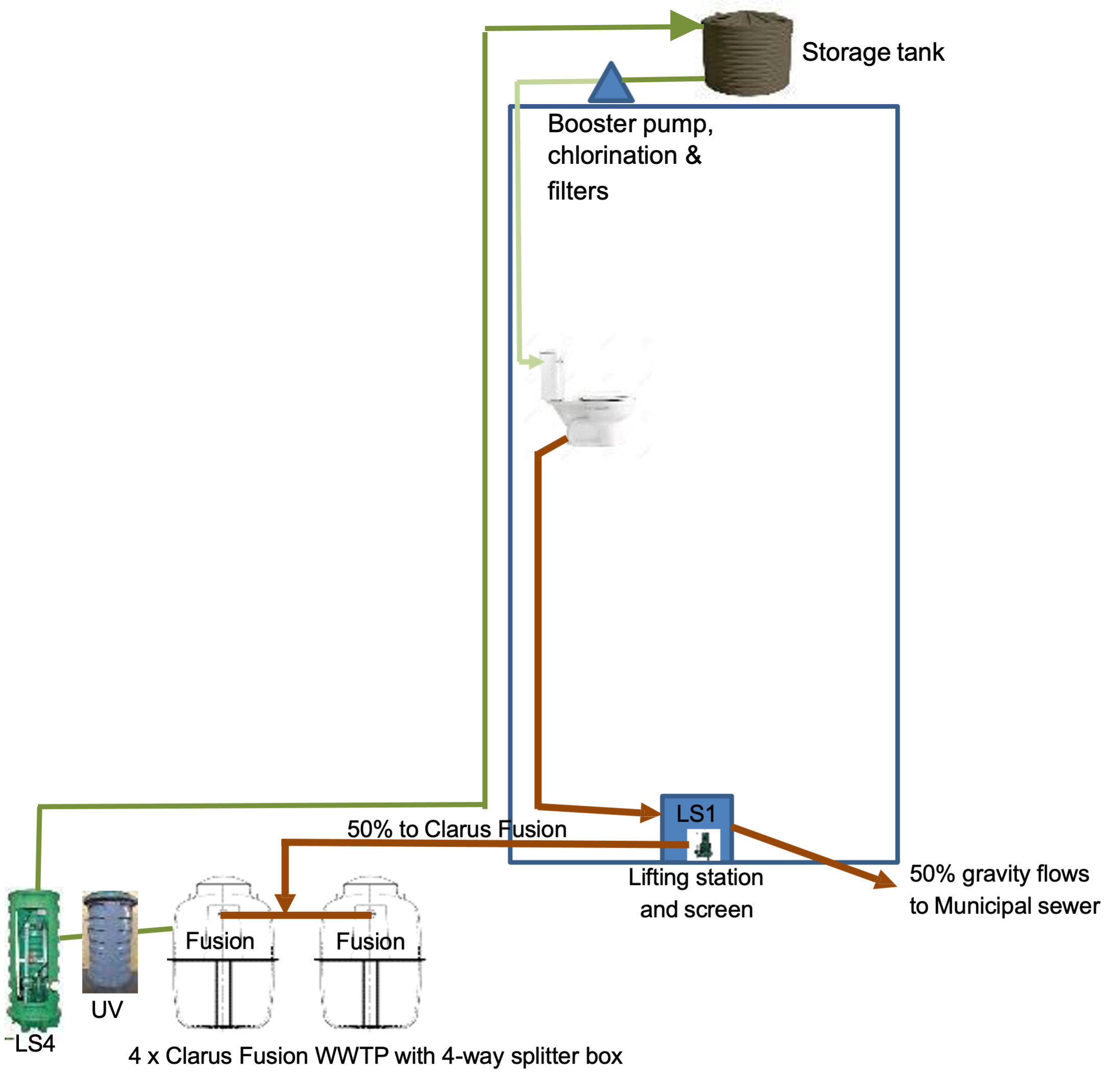

Basic Layout of the Fusion® system

1. When a toilet is flushed, the booster pump will start and deliver water from the tank to the toilet under pressure. A small amount of chlorine is dosed into the system, ensuring the water in the toilet is bacteria free.

2. As the tank level drops, a float switch in the tank will demand water from LS4. The pump will start and transfer water to the storage tank.

3. As the level in LS4 drops, it will demand raw sewage from LS1.

4. The pump at LS1 will start and feed raw sewage to the Clarus Fusion WWTP, where it is treated and gravity flows to LS4 via a UV for sterilization.

5. If LS1 is full and there is no demand from LS4, the excess sewage gravity overflows to the municipal sewer.

6. If there is a high level in LS4, the backup pump starts and waste the excess treated effluent to the municipal sewer.

7. There is a municipal backup to fill the storage tank if needed.

Advantages of the Fusion Wastewater Treatment System

Minimal visual impact and occupies a small footprint.

As the entire system is installed underground, it is out of sight with the only visible components being the green lids and vent pipe. No land is taken- up as movement over it is possible and can even be incorporated as part of the garden.

Maintenance requirements are minimal

As no skilled labour or as in most cases no daily attendance to the plant is required there is no running maintenance required. If you do have a Hand rake or Auto Screen at the inlet of the plant you have to clear all the Debry from the screen on a daily basis.